We started off meeting a couple of her friends, Jed and Cindy, for breakfast at 9 AM that live near the beer place. They were really nice and I enjoyed their company.

The class started at 11 AM and it was just a few blocks from where we had breakfast.

It was supposed to be us and another couple, but the other couple didn't show up so it was just us. I liked that because we got more personalized attention.

He poured us different types of beer to sample throughout the class. We also sampled three types of mead which I was excited to try. It was delicious! I always thought it was like sweet beer. It is actually just fermented honey. Surprisingly it tastes most similar to a white wine. He uses locally harvested honey which is neat. We could pick up on the florals, some pine, and various spicy notes. Whatever the bees foraged on really came out in the end result. Much more so than you can taste in just straight honey.

The instructor started soaking some barely malt and then cooking it around 6:30 in the morning. This is Amy stirring it after we dropped a satchel of crystal malt into it.

Here we have transferred the fresh malt from the kettle into the fermenter and are adding some canned malt. We added a can of hopped malt and a can of unhopped malt. He also added some hops to the mash in the kettle early in the morning.

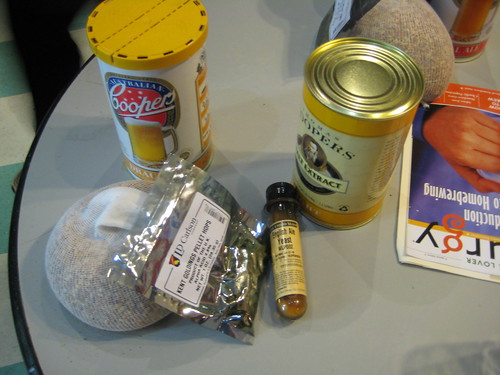

These are the two cans of malt we added, the satchel of crystal malt, the vial of yeast, and the package of finishing hops we added to the fermenter right before we sealed it up.

The blue barrel is just city tap water that the instructor pulled the day before and let it sit so the chlorine could escape.

The orange tub on the table is where he first soaked the barley malt in the morning. The black thing on the table behind it is the kettle where he cooked the mash after it soaked for a while. He cooked it at 180 degrees.

We will go back in about three weeks to bottle the beer and take it home. At that time we can adjust the beer if it is too hoppy, not hoppy enough, adjust the specific gravity etc. He said a lot of home brewers don't adjust their beer before they bottle it and said you miss the opportunity to make a really good beer by skipping this step.

We will also add some corn sugar before we bottle it. This is how you carbonate the beer. It gives the yeast an easily digestible food source which results in lots of carbon dioxide. He said they use corn sugar rather than table sugar because the latter can give your beer an off taste.

I think I could see myself doing it at home. You don't need nearly as much expensive equipment as I thought:

A five gallon bucket to use as a fermenter with an airtight lid and a water valve on top to let the excess gases out and keep bacteria from getting in.

A kettle to cook the mash and a turkey fryer burner. I have the burner, but I would probably want to use a kettle that hasn't been used for anything else.

A hydrometer to check specific gravity.

A bottle capper.

Some siphon tubing.

That's it! I have a friend that does a little home brewing who said I could borrow his gear before I invest in my own.