My greyhound can run faster than your honor student.

Tuesday, July 29, 2008

This is how I start sanitizing my beer equipment on brewing, racking or bottling days. This was taken on a racking day.

I have already added an ounce of iodophor to the carboy and am now adding 5 gallons of water. This will sanitize (not sterilize) the inside of the carboy which is what the beer will be racked into from the primary fermenter.

After the carboy is filled up I siphon it into a plastic container we got just for sanitizing. Doing this will sanitize the inside of the hose, and then I drop the whole hose into the container to sanitize the outside of it. We also put all of the equipment that will come into contact with the beer into the container.

I have already added an ounce of iodophor to the carboy and am now adding 5 gallons of water. This will sanitize (not sterilize) the inside of the carboy which is what the beer will be racked into from the primary fermenter.

After the carboy is filled up I siphon it into a plastic container we got just for sanitizing. Doing this will sanitize the inside of the hose, and then I drop the whole hose into the container to sanitize the outside of it. We also put all of the equipment that will come into contact with the beer into the container.

Tuesday, July 22, 2008

I checked the specific gravity of the mead and beer tonight and the alcohol content of the mead is about 9.9% and the beer only changed a little bit since the last time I checked and it is between 4.2% and 4.4%.

The beer hasn't changed much because the fermentation really slowed down after I checked it last and I didn't add more yeast until just a few days ago on Friday. It took a couple days for the yeast to really get going again. Because of the way the beer is bubbling now I think it should be ready for bottling by this weekend.

You have to sanitize everything that comes into contact with your beer. The easiest way is to mix up five gallons of iodine solution in the fermenter and throw all of your equipment in there. That works great for most of my stuff but there are a few things that stick up well above the top of the bucket. Also on nights like tonight when I just need my thief and hydrometer it is wasteful to mix up a full five gallons of solution, but the thief is one of the long things that stick out over the top of the bucket.

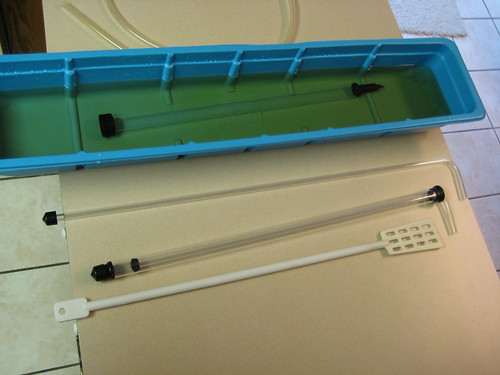

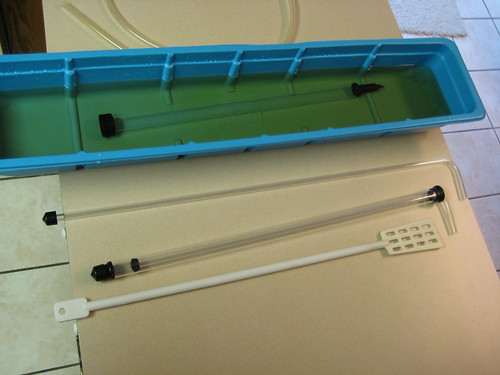

Well I had a brainstorm and came up with the perfect solution. I went to the hardware store and bought one of those plastic troughs you use to wet wallpaper rolls. It cost $3 and one gallon of iodophor solution is the perfect amount to adequately cover everything. Here is a picture of it in action.

The thief is in the trough being sanitized and it is what I use to pull a sample out of the carboys for testing.

On the counter next to the trough is a racking cane. I don't use it because I bought an autosiphon, but the cane came with the bottle filler so I keep it just in case.

The next thing on the counter is the autosiphon. This is a racking cane inside of a tube with an airtight seal between the two. You pull the racking cane out and then push it back in and it automatically starts your siphon going. You don't have to suck on the end of the tube to get it going and contaminate things. HIGHLY recommended.

The last item is a food grade high temperature plastic stirring paddles for stirring the wort in the brew kettle.

I took this picture a couple weeks ago after I racked the beer from the primary fermenter to the carboy. The stuff in the bottom are the dissolved hop pellets and yeast hulls. The tube is the autosiphon with the flexible tubing attached to it and is of course what I used for the transfer.

The beer hasn't changed much because the fermentation really slowed down after I checked it last and I didn't add more yeast until just a few days ago on Friday. It took a couple days for the yeast to really get going again. Because of the way the beer is bubbling now I think it should be ready for bottling by this weekend.

You have to sanitize everything that comes into contact with your beer. The easiest way is to mix up five gallons of iodine solution in the fermenter and throw all of your equipment in there. That works great for most of my stuff but there are a few things that stick up well above the top of the bucket. Also on nights like tonight when I just need my thief and hydrometer it is wasteful to mix up a full five gallons of solution, but the thief is one of the long things that stick out over the top of the bucket.

Well I had a brainstorm and came up with the perfect solution. I went to the hardware store and bought one of those plastic troughs you use to wet wallpaper rolls. It cost $3 and one gallon of iodophor solution is the perfect amount to adequately cover everything. Here is a picture of it in action.

The thief is in the trough being sanitized and it is what I use to pull a sample out of the carboys for testing.

On the counter next to the trough is a racking cane. I don't use it because I bought an autosiphon, but the cane came with the bottle filler so I keep it just in case.

The next thing on the counter is the autosiphon. This is a racking cane inside of a tube with an airtight seal between the two. You pull the racking cane out and then push it back in and it automatically starts your siphon going. You don't have to suck on the end of the tube to get it going and contaminate things. HIGHLY recommended.

The last item is a food grade high temperature plastic stirring paddles for stirring the wort in the brew kettle.

I took this picture a couple weeks ago after I racked the beer from the primary fermenter to the carboy. The stuff in the bottom are the dissolved hop pellets and yeast hulls. The tube is the autosiphon with the flexible tubing attached to it and is of course what I used for the transfer.

Sunday, July 20, 2008

Here is a picture of our mead and ale fermenting. The mead is in the carboy on the left and ale is on the right.

Notice the clarity of the mead. Last Wednesday I went downstairs to check on it and it still looked like lemonade. Completely opaque. I went downstairs on Friday and it was totally clarified! What a surprise. They have both been fermenting for three weeks. The beer is probably a little over 4% alcohol and when we checked the mead a week ago it was 8%, but the as vigorously as it has been fermenting I'll bet it could be over 10% now. I plan to check both within the next few days.

I didn't think a movie from my digital camera would have enough light or resolution to show the massive amounts of tiny bubbles that continuously rise to the surface day and night, but you can actually see it pretty well. The sound in the background is the air conditioner running. The mead is actually pretty quiet. At the end you can see a bubble of gas escaping in the air lock at the top.

Notice the clarity of the mead. Last Wednesday I went downstairs to check on it and it still looked like lemonade. Completely opaque. I went downstairs on Friday and it was totally clarified! What a surprise. They have both been fermenting for three weeks. The beer is probably a little over 4% alcohol and when we checked the mead a week ago it was 8%, but the as vigorously as it has been fermenting I'll bet it could be over 10% now. I plan to check both within the next few days.

I didn't think a movie from my digital camera would have enough light or resolution to show the massive amounts of tiny bubbles that continuously rise to the surface day and night, but you can actually see it pretty well. The sound in the background is the air conditioner running. The mead is actually pretty quiet. At the end you can see a bubble of gas escaping in the air lock at the top.

Sunday, July 13, 2008

I racked my beer again yesterday and checked the specific gravity. It went down only another point in the last week, but it tastes really good. It will still be very drinkable, just not as high of an alcohol content as it is supposed too. Actually that might make it a good summer beer! It is still around 4% ABV. I plan on bottling it next weekend. I think I am going to put a little yeast nutrient and yeast energizer in the fermenter today to see if that might help things along a bit.

We also racked our mead and checked its SG. It is at about 8% alcohol now! We drank the 6 ounce sample we needed to check the SG and it was so good we pulled another glass to drink. If it tastes that good now I think it will be amazing in a few months. It has a beautiful light straw color. We used Champaign yeast because we wanted a dry wine rather than a sweet one, and the Champaign taste is coming through nicely. We were going to make half of this batch still and half sparkling, but we think we might make it all sparkling now. Still not 100% sure yet, but that's what makes it fun.

After we took care of our 10 gallons of deliciousness we took the Two Brother's Brewery tour. I've done it once before with my parents but Amy had not taken it. Afterwards we were sitting in the tap house and I was trying a Cane & Ebel and think I have fallen in love with Simcoe hops. They are a fairly new variety introduced in 2000. I haven't seen them at my local homebrew shop and I think right now they are available mostly to commercial brewers. If I can't find them for my next batch I think I will try Cascade hops because I have read people describe Simcoe hops as Cascade on steroids.

The brewery also has a homebrew shop and I picked up 3.3 pounds of amber liquid malt extract for my next batch of beer and Amy got a large can of sterilized peach puree for an upcoming batch of mead. I think for the other half of the malt in my next beer I will use a powdered malt extract, but I don't know if I want that to be an amber or a light. I still have to do some more research. I am thinking about buying a little bit more than I need for the batch and use the extra as priming sugar rather than corn sugar.

If you describe the homebrew process to somebody it sounds like a lot of work and complexity, and it is if you had to do it all at one time. But because brewing and racking and bottling all happen on different days separated each by several weeks it is really not that bad. I actually look forward to each process. Each process takes about two hours from start to finish. Brew day probably takes a little longer because you have to boil your wort for one hour, but that is more just relaxing than actually working.

I had to go into work today for a little bit to check on a database that had been updated yesterday, and Amy is in Kansas to see a patient for the day. I am going to start some laundry, put away some brewing gear from yesterday, and do some puttering yard work. Don't know if I will cut the grass, but I plan on at least spraying and/or digging some weeds, pick up dog poop, light pruning, and maybe organize the garage a little bit. My aquarium has not had a partial water change in WAY too long. I should do that today too. Oh yeah, a bike ride would also be a good idea. The weather here is perfect today.

We also racked our mead and checked its SG. It is at about 8% alcohol now! We drank the 6 ounce sample we needed to check the SG and it was so good we pulled another glass to drink. If it tastes that good now I think it will be amazing in a few months. It has a beautiful light straw color. We used Champaign yeast because we wanted a dry wine rather than a sweet one, and the Champaign taste is coming through nicely. We were going to make half of this batch still and half sparkling, but we think we might make it all sparkling now. Still not 100% sure yet, but that's what makes it fun.

After we took care of our 10 gallons of deliciousness we took the Two Brother's Brewery tour. I've done it once before with my parents but Amy had not taken it. Afterwards we were sitting in the tap house and I was trying a Cane & Ebel and think I have fallen in love with Simcoe hops. They are a fairly new variety introduced in 2000. I haven't seen them at my local homebrew shop and I think right now they are available mostly to commercial brewers. If I can't find them for my next batch I think I will try Cascade hops because I have read people describe Simcoe hops as Cascade on steroids.

The brewery also has a homebrew shop and I picked up 3.3 pounds of amber liquid malt extract for my next batch of beer and Amy got a large can of sterilized peach puree for an upcoming batch of mead. I think for the other half of the malt in my next beer I will use a powdered malt extract, but I don't know if I want that to be an amber or a light. I still have to do some more research. I am thinking about buying a little bit more than I need for the batch and use the extra as priming sugar rather than corn sugar.

If you describe the homebrew process to somebody it sounds like a lot of work and complexity, and it is if you had to do it all at one time. But because brewing and racking and bottling all happen on different days separated each by several weeks it is really not that bad. I actually look forward to each process. Each process takes about two hours from start to finish. Brew day probably takes a little longer because you have to boil your wort for one hour, but that is more just relaxing than actually working.

I had to go into work today for a little bit to check on a database that had been updated yesterday, and Amy is in Kansas to see a patient for the day. I am going to start some laundry, put away some brewing gear from yesterday, and do some puttering yard work. Don't know if I will cut the grass, but I plan on at least spraying and/or digging some weeds, pick up dog poop, light pruning, and maybe organize the garage a little bit. My aquarium has not had a partial water change in WAY too long. I should do that today too. Oh yeah, a bike ride would also be a good idea. The weather here is perfect today.

Thursday, July 03, 2008

Just got back from a 9.8 mile bike ride. Had a Smithwick's and a Dogfish Head 90 Minute IPA (I'm feeling good!) I'm going to take a shower and then check the specific gravity of the beer we brewed last week. I did two things wrong with it. 1) I did not aerate the wort and 2) pitched the yeast while the wort was too warm. The first day the airlock was bubbling almost continuously. After that it was bubbling about every 3 minutes or 3.5 minutes which I think seems on the slow side. I think it stopped bubbling today. Checking the specific gravity will tell me how far along it is to being beer. I might be surprised and it is already beer. It could go either way. We'll see.

Wednesday, July 02, 2008

Tuesday, July 01, 2008

Last week I went for a 9.7 mile bike ride and tonight I rode for 11.7 miles. My legs could have gone more, but my butt was getting saddle-sore.

Today Mitch is a big boy and is 5 years old! In honor of his birthday I thought I would post a video of him I took a few weeks ago but never got around to posting.

I was trying to get him riled up to play by making growling sounds and thumping the bed. It works sometimes, but this time all he did was stick his tongue out of the side of his mouth. I was laughing so hard I couldn't keep the camera steady.

My beer was going gangbusters the first day, but today it slowed to a bubble every 30 to 40 seconds. I did some looking on some homebrew forums and it might be because I did not aerate the wort enough before I pitched the yeast. I also added the yeast when the wort was possible too warm. You are supposed to get the temperature down close to 70 degrees, but I added it when it was 105 degrees. I hope to rack it to a carboy Friday are Saturday. I think I read somewhere that doing that can sometimes give the yeast a little nudge to start working again. I will also measure the specific gravity again to see how far along it is. (i.e. how much of the sugars have been converted to alcohol)

Today Mitch is a big boy and is 5 years old! In honor of his birthday I thought I would post a video of him I took a few weeks ago but never got around to posting.

I was trying to get him riled up to play by making growling sounds and thumping the bed. It works sometimes, but this time all he did was stick his tongue out of the side of his mouth. I was laughing so hard I couldn't keep the camera steady.

My beer was going gangbusters the first day, but today it slowed to a bubble every 30 to 40 seconds. I did some looking on some homebrew forums and it might be because I did not aerate the wort enough before I pitched the yeast. I also added the yeast when the wort was possible too warm. You are supposed to get the temperature down close to 70 degrees, but I added it when it was 105 degrees. I hope to rack it to a carboy Friday are Saturday. I think I read somewhere that doing that can sometimes give the yeast a little nudge to start working again. I will also measure the specific gravity again to see how far along it is. (i.e. how much of the sugars have been converted to alcohol)